By Crystal Ye | 24 February 2023 | 0 Comments

The type of warehouse racking weight capacity /pallet racking weight capacity

The type of company's business will decide the type of warehouse it needs. Therefore, although all warehouses have similar characteristics, the products to be stored will determine the design and construction of the warehouse and the installation of the storage system.

In addition, the nature of the product will affect the delivery rate of goods, transportation between different warehouse areas, storage of goods, preparation of orders, integration of goods, and inventory management. However, not all goods are the same, so their storage types and the logistics processes involved are also different.

Unit load is a homogeneous grouping of a group of products, these products are arranged on a support or platform to facilitate the handling and transfer of goods, so as a logistics unit.

The purpose of cargo grouping is to minimize the number of movements to facilitate its transportation and storage.

Load types can be classified in many ways:

light duty loading capacity

These goods can be carried with one hand and are usually unified in one package. For example, a box of juice or a pack of beer.

Medium duty loading capacity

They are slightly larger than the above-mentioned loading , and may weigh up to 10-20 kg, but they can still be carried by hand.

Small and medium-sized goods can be stored in the carton mobile racking system and large-span racking. Although there are differences between these two types of picking solutions, for these types of products, they are both the best choices due to their size and weight.

In the Carton Flow Rack system, the first task is to promote high product turnover (for example, warehouses in the food distribution chain such as Eroski and Caprabo), while for Longspan Shelving, direct access to goods is sought .

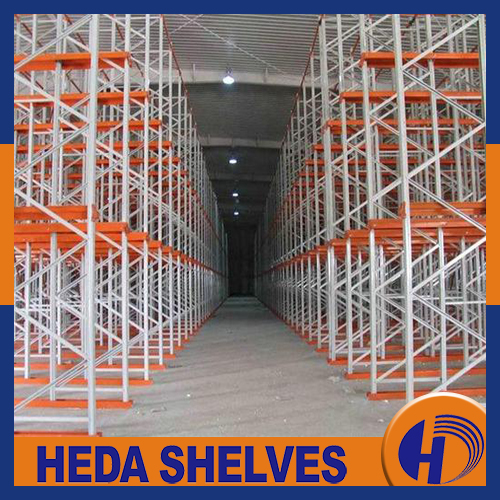

Large or pallet loads

T HESE is where the larger products require standardized packaging and are grouped for handling pallets. Such loads cannot be handled manually, but are handled by mechanical means such as forklifts.

Pallet loads can be stored using a variety of storage solutions. Everything depends on the function of the warehouse, product type, available area, etc.

Some companies need to obtain goods immediately in daily intralogistics operations. In this case, the warehouse will be equipped with a storage system with direct access to the pallets.

However, other companies will prioritize the maximum optimization of available space, including floor and height, so a compact and high-density storage system will be the most suitable solutions.

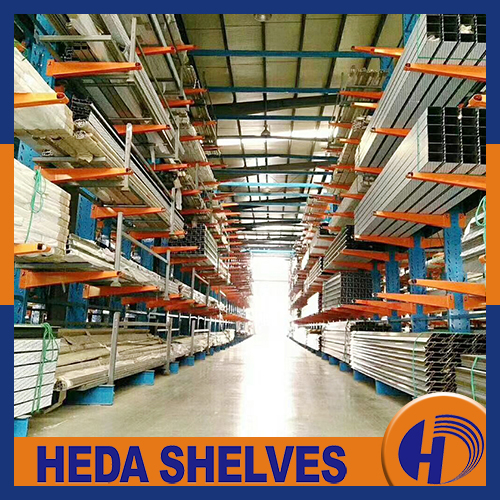

Bulky cargo

These are large loads that sometimes cannot even be stacked. They can range from large appliances such as refrigerators to construction items such as iron beams.

When the load is very large, as mentioned above, special mechanical equipment (such as a crane) is required to move them.

Cantilever racks /structural cantilever/lumber racking/cantilever shelving can meet this large load storage demand.

Special size load

These are extremely large and almost always heavy loads (such as structural elements used to build bridges), even exceeding the size of the transport vehicle, requiring support vehicles, special traffic arrangements during transport, etc.

First in first out, first in last out, easily solve the problem of industrial storage and logistics

How to budget for a warehouse racking in a warehouse

Leave a Reply

Your email address will not be published.Required fields are marked. *

POPULAR BLOG

- Advantages of Gondola Shelving - Why It Is Popular In Retailing

- 9 Ideas To Attract Customers By In-store Merchandising Displays

- Advantages & Features of Pallet Rack Mezzanine for Warehouse

- Fruit And Veg Display Stand - The Best Types & Layout Suggestions

- How To Boost Sales for Shops With Product Display

CATEGORIES