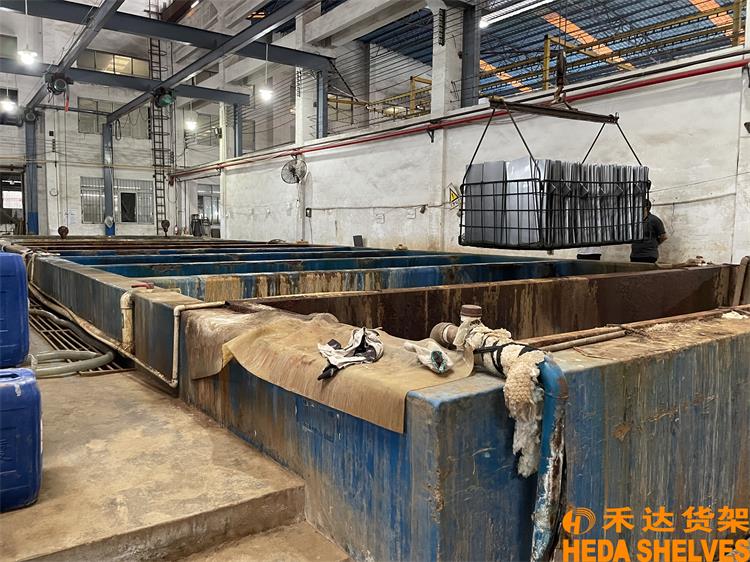

Proceso de laminado

corte-punzonado-doblado-soldadura-pulido-ácido lavado,fosfatado-revestimiento en polvo seco-embalaje

Punzonado automático

Cuenta con una línea de producción de punzonado continuo totalmente automática, que se utiliza para completar el punzonado del perfil de la columna antes de la unión. La precisión del espaciado de los orificios puede alcanzar los 0,02 mm y el error acumulativo de la longitud de la columna no supera los 2 mm.

Formación laminada en frío

La columna del estante y varias vigas están unidas por su propia unidad de formación de doblado en frío automática, que se coloca y corta automáticamente de acuerdo con la longitud requerida, y el error de dimensión de longitud no es más de 1 mm.

Soldadura

Todos están soldados con máquinas de soldar protegidas con dióxido de carbono, lo que garantiza la calidad de la soldadura y la apariencia suave de la soldadura.

Columna

①Material: placa de acero laminado en frío;

②Color: azul (se puede personalizar según los requisitos del cliente);

③La columna y la riostra horizontal y la riostra diagonal están todas conectadas por pernos galvanizados;

④Cuando está completamente cargada, la desviación máxima de la columna no es más de 1/1000H;

⑤La parte inferior de la columna del estante para trabajo pesado está equipada con una placa inferior, y la placa inferior y el suelo están conectados mediante pernos de expansión para garantizar la estabilidad del estante;

⑥La altura total de la columna del bastidor se determina de acuerdo con los requisitos de diseño, la distancia del orificio de la columna es de 50 y 75 mm, la altura de la capa se puede ajustar libremente y el error acumulativo de la distancia del orificio es de ± 1 mm;

⑦ Uso de columna convexa con sección transversal optimizada y gran capacidad de carga; (Seleccione columnas de cojinetes de acuerdo con los requisitos de diseño, columnas de uso común: columnas de tamaño mediano 55*50, columnas de servicio pesado: 90*70/108*85).

Haz

①Material: placa de acero laminado en frío;

②Color: naranja (se puede personalizar según los requisitos del cliente);

③Cada viga está equipada con un pasador de seguridad para aumentar el factor de seguridad;

④ Cuando la viga está completamente cargada, su deflexión máxima no es más de 1/200L;

⑤La viga y la columna están conectadas por dientes colgantes, que están incrustados sin inserción de espacios, con una gran área de contacto y buena confiabilidad;

⑥Uso de vigas transversales o vigas P, etc., con secciones transversales optimizadas, fuerte resistencia a la flexión y capacidad de carga; (La selección de vigas transversales se basa en las opciones de luz y carga, dimensiones convencionales: las vigas de soldadura son 80*45, 100*45, 120*45, 140*45,).