What is palletization and some of its benefits in warehouse storage?

Palletization is a common method of storing and transporting goods in warehouses. It involves placing goods on flat platforms called pallets, which can be easily moved by forklifts, pallet jacks, or other equipment. Palletization offers many advantages for warehouse operations, such as improving space utilization, efficiency, and safety.

In this article, we will explain the definition and basic principles of palletization, the key benefits of palletization, the application of palletization in modern warehousing, and how to effectively implement the palletization strategy.

Definition and basic principles of palletization

The concept of palletization

Palletization is a logistical process that involves placing goods or materials, either packaged or bulk, onto pallets. The pallet serves as a base for the goods and materials, facilitating their efficient storage, handling and transport as a unit load. Palletization simplifies the process of placing items on a pallet so they can be transported and/or stored.

Types and specifications of pallets

There are different types and specifications of pallets, depending on the size, shape, weight, and nature of the goods, as well as the requirements of the warehouse and the destination. Some of the common types of pallets are:

- Stringer pallets: These are pallets with two or more parallel pieces of timber (called stringers) that support the deck boards. Stringer pallets can be lifted from two sides only.

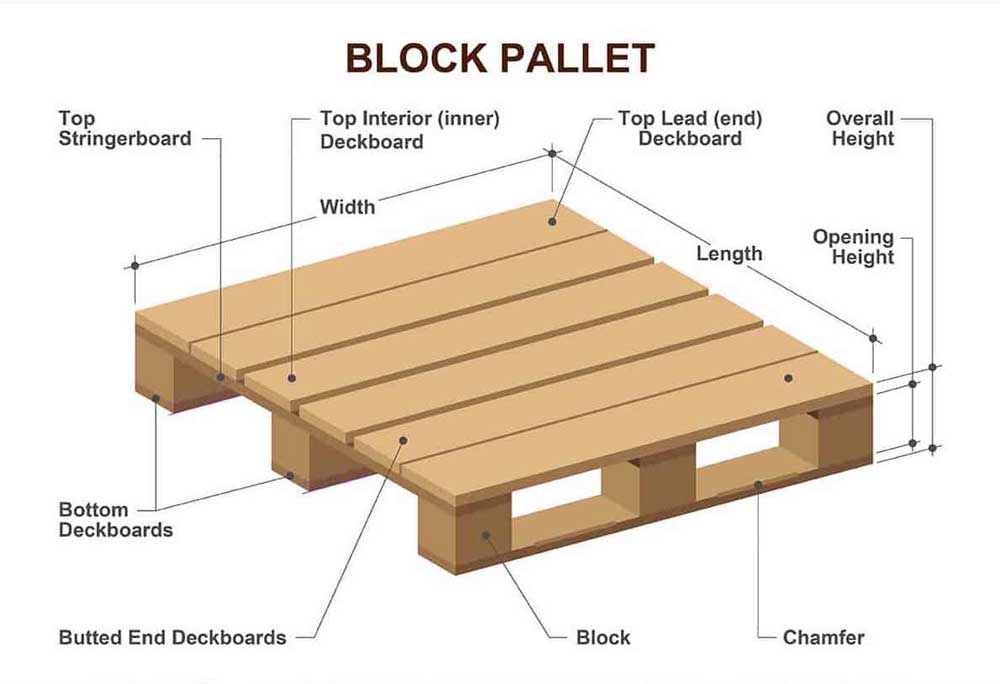

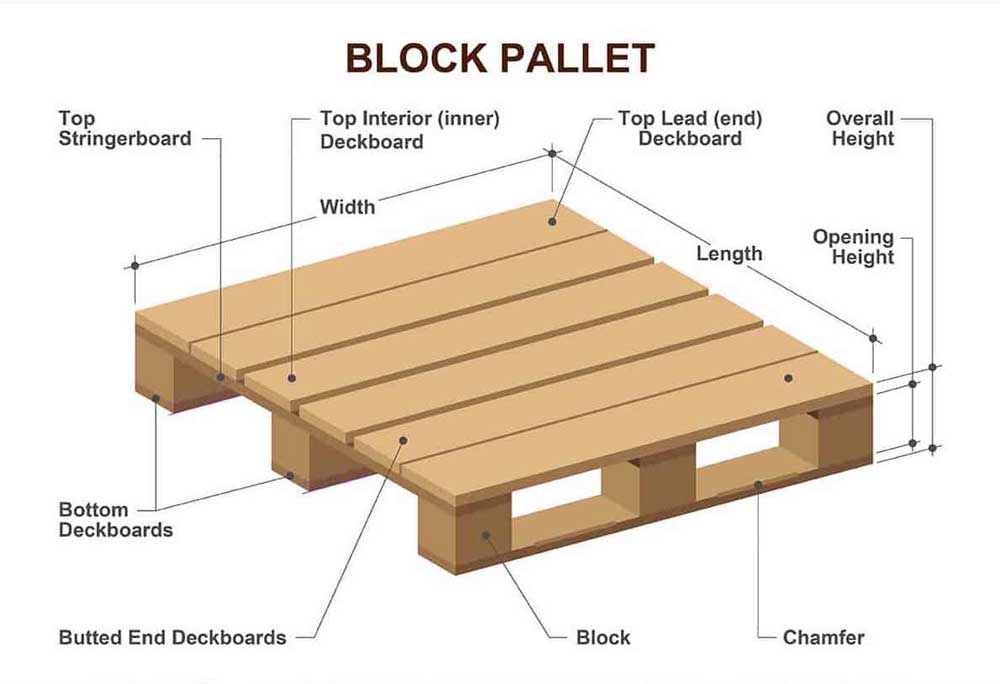

- Block pallets: These are pallets with blocks of wood or plastic (called blocks) that support the top and bottom deck boards. Block pallets can be lifted from four sides and are more durable and stable than stringer pallets.

- Euro pallets: These are pallets that conform to the European standard dimensions of 800 mm × 1,200 mm × 144 mm. Euro pallets are widely used in Europe and other regions that follow the same standard.

- ISO pallets: These are pallets that conform to the International Organization for Standardization (ISO) dimensions of 1000 x 1200 mm. ISO pallets are widely used in North America and other regions that follow the same standard.

Pallet material

The material of the pallet is an important factor to consider when choosing a pallet for a specific application. The material affects the weight, durability, cost, and environmental impact of the pallet. The most common materials for pallet construction are:

- Wood: Wood is the most widely used material for pallets, as it is cheap, abundant, strong, and easy to repair. Wood pallets can be made from hardwood or softwood, or a mixture of both. Wood pallets are also recyclable and biodegradable, which reduces their environmental impact. However, wood pallets are also heavy, prone to splintering, and susceptible to moisture, insects, and fungi, which may affect their quality and hygiene.

- Plastic: Plastic is a synthetic material that is lightweight, durable, and resistant to moisture, insects, and fungi. Plastic pallets can be made from recycled or virgin plastic, and they can be molded into various shapes and sizes. Plastic pallets are easy to clean and sanitize, and they are ideal for hygienic applications such as food and pharmaceutical industries. However, plastic pallets are difficult to repair, and non-biodegradable, which increases their environmental impact.

- Metal: Metal is a strong and durable material that can withstand high temperatures, pressures, and loads. Metal pallets can be made from steel, aluminum, or other alloys, and they can be welded or bolted together. Metal pallets are fireproof, rust-resistant, and long-lasting, and they are suitable for heavy-duty applications such as industrial or military use. However, metal pallets are also heavy, costly, and noisy, and they may damage the products or the equipment during handling.

- Paper: Paper is a lightweight and inexpensive material that can be used to make pallets from corrugated cardboard, honeycomb, or molded pulp. Paper pallets are recyclable and biodegradable, and they can reduce the shipping costs and the environmental impact of the pallets. However, paper pallets are also weak, fragile, and vulnerable to moisture, tearing, and crushing, and they may not be suitable for long-term or heavy-duty use.

Palletization is a useful method of warehouse storage that can optimize space, time, and cost. However, it requires careful planning and selection of the appropriate pallets for the goods and materials to be stored or transported.

Advantages of palletization

Palletization offers many benefits for warehouse storage, such as:

Improvement of space utilization

Palletization allows for better use of the available space in the warehouse, by enabling the stacking of goods and the optimization of the vertical dimension. Palletization also reduces the need for individual packaging and wrapping of goods, which saves space and material costs. Palletization also allows for the standardization and uniformity of the goods, which facilitates the arrangement and alignment of the goods in the warehouse.

Improvement of warehousing efficiency

Palletization improves the efficiency and productivity of the warehouse operations, by reducing the time and labor required for handling, storing, and transporting the goods. Palletization enables the use of mechanized equipment, such as forklifts, pallet jacks, or conveyors, which can move multiple goods at once, rather than one by one. Palletization also simplifies the inventory management and tracking of the goods, by using labels, barcodes, RFID tags, or other identifiers that can be scanned or read by the equipment or the staff.

Reduce manual handling and risk of damage

Palletization reduces the manual handling and the risk of damage of the goods, by providing stability and protection to the goods and minimizing the contact and movement of the goods. Palletization prevents the goods from falling, sliding, or shifting during handling, storage, or transportation, which reduces the chance of breakage, loss, or contamination. Palletization also protects the goods from dust, moisture, insects, rodents, or other environmental factors that could affect the quality and safety of the goods.

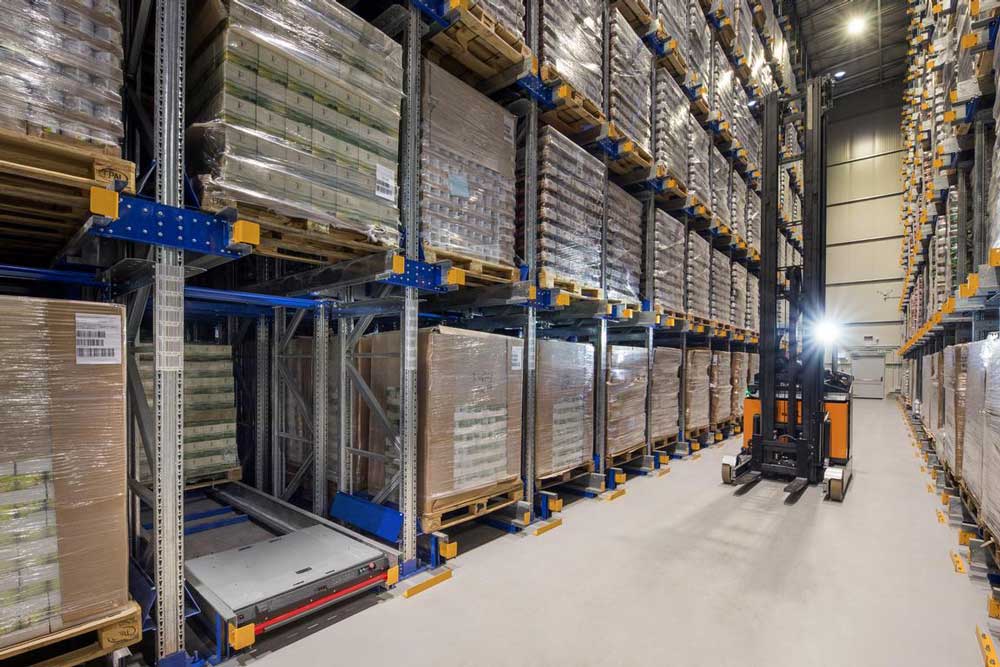

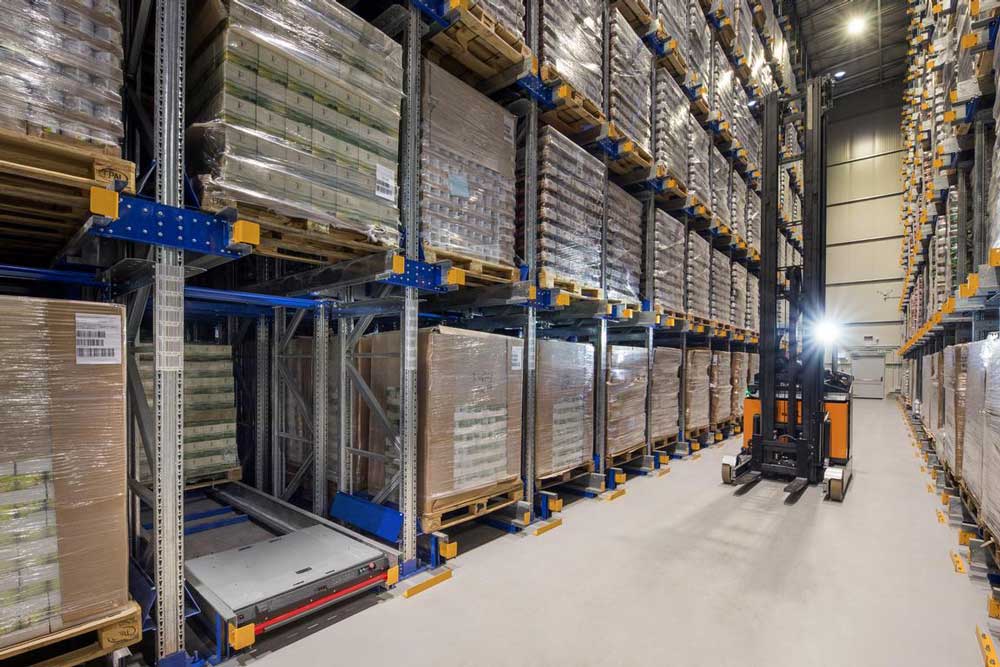

Palletization in warehouse

Palletization can improve the efficiency, safety, and space utilization of warehouse operations. However, not all warehouse shelves are suitable for palletization, and not all products are suitable for storage in palletized warehouses.

What are the warehouse shelves suitable for palletization?

Warehouse shelves are the structures that support and organize the pallets in a warehouse. There are different types of warehouse shelves, each with its own advantages and disadvantages. Some of the most common types of warehouse shelves suitable for palletization are:

- Selective pallet rack: This is the most widely used type of warehouse shelf, which allows direct access to every pallet. It is ideal for warehouses that store a variety of products with different sizes, weights, and turnover rates. Selective pallet rack is easy to install and adjust, but it requires more aisle space and has lower storage density than other types of warehouse shelves.

- Drive-in rack: This is a high-density type of warehouse shelf, which allows forklifts to drive into the rack and store pallets on rails. It is ideal for warehouses that store large quantities of the same or similar products, and use a last-in, first-out (LIFO) inventory system. Drive-in rack can reduce aisle space and increase storage capacity, but it has limited selectivity and can cause damage to the pallets and the rack.

- Pallet flow rack: This is a dynamic type of warehouse shelf, which uses gravity rollers or skate wheels to move pallets from the loading end to the picking end. It is ideal for warehouses that store perishable products or products with high turnover rates, and use a first-in, first-out (FIFO) inventory system. Pallet flow rack can improve product flow and order accuracy, but it has high installation and maintenance costs and requires special pallets.

Other types of warehouse shelves suitable for palletization include double deep rack, push back rack, carton flow rack, and stack racks. The choice of warehouse shelf depends on the warehouse layout, the product characteristics, the inventory management system, and the budget.

What type of products are suitable for storage in palletized warehouses?

Palletized warehouses can store a wide range of products, as long as they meet the following criteria:

- They can be stacked on pallets without causing damage or instability. Products that are fragile, irregular, or prone to shifting should be avoided or secured with straps, shrink wrap, or other methods.

- They can fit on standard pallet sizes, or custom pallets can be used. The most common pallet size in the US is 48 x 40 inches, but other sizes are also available. Products that are too large or too small for pallets should be avoided or modified.

- They can withstand the environmental conditions of the warehouse. Products that are sensitive to temperature, humidity, light, or dust should be stored in palletized warehouses that have climate control, ventilation, or protection systems.

Some examples of products that are suitable for storage in palletized warehouses are:

- Food and beverage products, such as canned goods, bottled drinks, dry goods, and frozen foods. These products can benefit from palletization, as it can improve hygiene, safety, and shelf life. However, they may require special pallets, such as plastic pallets, that are easy to clean and resistant to moisture and pests.

- Industrial products, such as chemicals, metals, machinery, and spare parts. These products can benefit from palletization, as it can improve handling, storage, and transportation efficiency. However, they may require special pallets, such as metal pallets, that are strong and durable.

- Consumer products, such as clothing, electronics, books, and toys. These products can benefit from palletization, as it can improve inventory control, order fulfillment, and customer satisfaction. However, they may require special pallets, such as wood pallets, that are economical and versatile.

Palletization is a useful method of warehouse storage that can optimize space, time, and cost. However, it requires careful planning and selection of the appropriate warehouse shelves and products.

Application of palletization in modern warehousing

Palletization is widely used in modern warehousing, especially in industries that deal with large quantities and varieties of goods, such as e-commerce and retail. Some of the examples of the application of palletization in modern warehousing are:

Palletization and automated warehousing system

Palletization is an essential component of the automated warehousing system, which is a system that uses computerized and robotic equipment to perform the warehousing tasks, such as receiving, storing, picking, packing, and shipping the goods. Palletization enables the automated warehousing system to handle the goods efficiently and accurately, by using standardized and compatible pallets that can be recognized and manipulated by the equipment. Palletization also enhances the performance and reliability of the automated warehousing system, by reducing the errors and delays caused by human intervention or manual handling.

Application of palletization in e-commerce and retail industries

Palletization is widely used in the e-commerce and retail industries, which are industries that sell goods online or offline to consumers. Palletization helps the e-commerce and retail industries to cope with the high demand and the fast delivery of the goods, by enabling the quick and easy handling, storage, and transportation of the goods. Palletization also helps the e-commerce and retail industries to improve the customer satisfaction and loyalty, by ensuring the quality and safety of the goods and reducing the risk of damage or loss.

How to effectively implement the palletization strategy

Palletization is a beneficial strategy for warehouse storage, but it also requires careful planning and execution to achieve the best results. Some of the steps to effectively implement the palletization strategy are:

Choose the right pallet type

The first step is to choose the right pallet type for the goods, the warehouse, and the destination. The pallet type should match the size, shape, weight, and nature of the goods, as well as the requirements of the warehouse and the destination. The pallet type should also comply with the standards and regulations of the industry and the region, such as the dimensions, the load capacity, the material, and the design. The pallet type should also be cost-effective, durable, recyclable, and environmentally friendly.

Train and educate employees

The second step is to train and educate the employees on the palletization process and the best practices. The employees should be familiar with the pallet types, the palletizing equipment, the palletizing methods, and the palletizing rules. The employees should also be aware of the benefits and the challenges of palletization, and the ways to overcome them. The employees should also be motivated and incentivized to adopt and follow the palletization strategy.

Coordination with suppliers and partners

The third step is to coordinate with the suppliers and the partners on the palletization strategy. The suppliers and the partners are the parties that provide or receive the goods from the warehouse, such as the manufacturers, the distributors, the retailers, or the customers. The coordination with the suppliers and the partners should ensure the compatibility and the consistency of the pallets and the goods, as well as the efficiency and the accuracy of the palletizing process. The coordination with the suppliers and the partners should also involve the communication and the feedback on the palletization strategy, and the improvement and the innovation of the palletization strategy.

Conclusion

Palletization is a common and effective method of storing and transporting goods in warehouses. It involves placing goods on flat platforms called pallets, which can be easily moved by forklifts, pallet jacks, or other equipment. Palletization offers many advantages for warehouse operations, such as improving space utilization, efficiency, and safety. Palletization is widely used in modern warehousing, especially in industries that deal with large quantities and varieties of goods, such as e-commerce and retail. Palletization requires careful planning and execution, which involves choosing the right pallet type, training and educating employees, and coordinating with suppliers and partners. Palletization is a beneficial strategy for warehouse storage, but it also requires continuous improvement and innovation to adapt to the changing needs and demands of the market.

Leave a Reply

- Advantages of Gondola Shelving - Why It Is Popular In Retailing

- 9 Ideas To Attract Customers By In-store Merchandising Displays

- Advantages & Features of Pallet Rack Mezzanine for Warehouse

- Fruit And Veg Display Stand - The Best Types & Layout Suggestions

- How To Boost Sales for Shops With Product Display