What is Teardrop Pallet Racking and Why You Should Use It in Your Warehouse(2024)

If you are seeking a trustworthy, adaptable, and economical storage solution for your warehouse, you may have encountered teardrop pallet racking as a potential option. But what is teardrop pallet racking, and how can it benefit your business? This article will elucidate everything you need to know about teardrop pallet racking, including its definition, features, advantages, disadvantages, and best practices. By the end of this article, you will be able to ascertain whether teardrop pallet racking is the right choice for your warehouse.

What is Teardrop Pallet Racking?

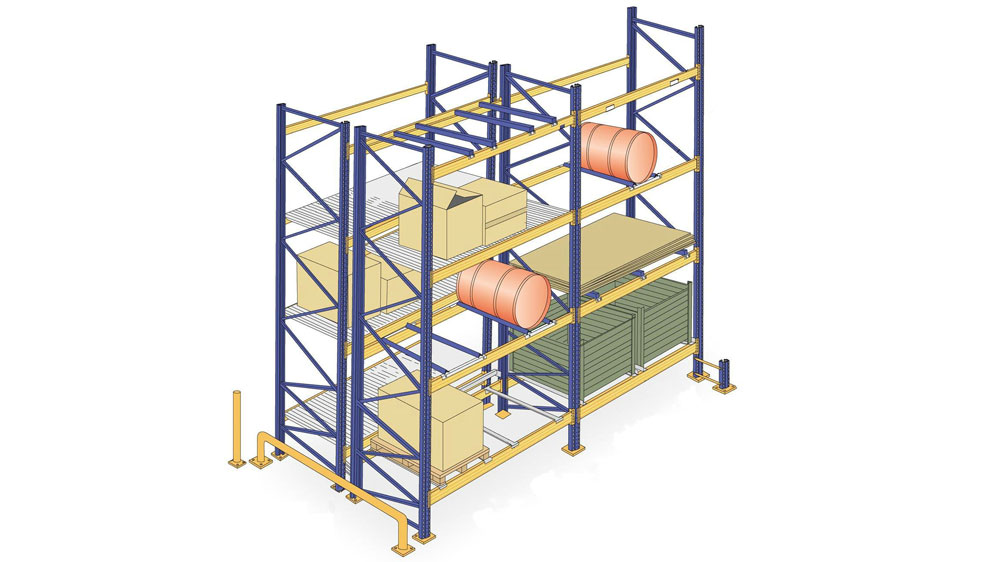

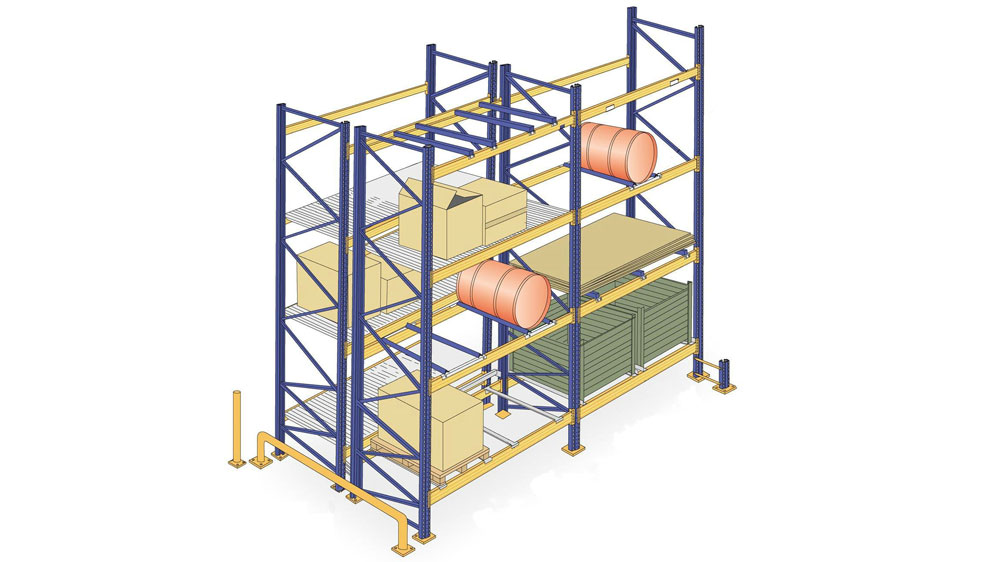

Teardrop pallet racking is a type of selective pallet racking system that uses a teardrop-shaped hole on the upright frames to connect the beams. The beams have a locking device that fits into the hole and secures the beam in place.

The teardrop hole enables easy and quick adjustment of the beam height, without the need for tools or hardware. Teardrop pallet racking is one of the most prevalent and preferred pallet racking systems in the market, due to its compatibility, flexibility, durability, and cost.

The Definition and Features of Teardrop Pallet Racking

Teardrop pallet racking is a storage system that comprises two main components: upright frames and beams.

The upright frames are the vertical columns that support the beams and the load. The beams are the horizontal bars that hold the pallets and the goods. The upright frames and beams are made of high-quality steel and are designed to withstand heavy loads and impacts.

The teardrop hole on the upright frames is the distinctive feature of teardrop pallet racking. The hole is shaped like a teardrop, with a larger opening at the bottom and a smaller opening at the top. The hole is spaced at 2-inch intervals along the height of the upright frame, allowing for multiple beam levels and configurations.

The beams have a locking device that fits into the teardrop hole and locks the beam in place. The locking device can be easily released by lifting the beam and sliding it out of the hole. This makes teardrop pallet racking very easy and quick to install, adjust, and reconfigure, without the need for tools or hardware.

The Advantages and Disadvantages of Teardrop Pallet Racking

Teardrop pallet racking has many benefits over other types of pallet racking systems, such as:

- Compatibility:

Teardrop pallet racking is compatible with most brands and models of pallet racking systems, as well as most types of forklifts and pallets. This means that you can mix and match different components and accessories from different manufacturers and suppliers, without worrying about compatibility issues. This also gives you more flexibility and options when designing and expanding your storage system.

- Flexibility:

Teardrop pallet racking is flexible and adaptable to your changing storage needs and preferences. You can easily and quickly adjust the beam height and position, as well as the number and size of the pallets, to accommodate different types of goods and inventory levels.

You can also add or remove components and accessories, such as wire decking, column protectors, row spacers, and cross bars, to enhance the functionality and safety of your storage system.

- Durability:

Teardrop pallet racking is durable and robust, as it is made of high-quality steel and has a powder-coated finish that protects it from corrosion and rust. Teardrop pallet racking can withstand heavy loads and impacts, as well as harsh environmental conditions, such as humidity, temperature, and dust. Teardrop pallet racking also has a long lifespan, as it requires minimal maintenance and repair.

- Cost:

Teardrop pallet racking is cost-effective and economical, as it has a low initial cost and a high return on investment. Teardrop pallet racking is widely available and easy to source, as it is manufactured and supplied by many companies and distributors. Teardrop pallet racking also has a low operating cost, as it saves space, time, and labor, and reduces the risk of damage and loss.

However, teardrop pallet racking also has some drawbacks, such as:

- Selectivity:

Teardrop pallet racking is a selective pallet racking system, which means that it allows direct access to each pallet and each SKU. This is beneficial for inventory management and order fulfillment, as it enables FIFO (first in, first out) and LIFO (last in, first out) methods.

However, this also means that teardrop pallet racking has a low storage density, as it requires more aisle space and floor space than other types of pallet racking systems, such as drive-in, drive-through, or push-back racking. This may limit the storage capacity and efficiency of your warehouse, especially if you have a large number of pallets or a small warehouse space.

- Stability:

Teardrop pallet racking is a freestanding pallet racking system, which means you have the option of leaving it unsecured to the floor or wall. This makes teardrop pallet racking more flexible and versatile, as it can be moved and reconfigured easily.

However, this also makes teardrop pallet racking less stable and more prone to tipping over, especially if it is overloaded, unevenly distributed, or improperly installed. This may pose a safety hazard for your workers and your goods, as well as a legal liability for your business.

Hence, we advise that you fasten the racking to the floor if your teardrop pallet racking exceeds three meters in height.

Why You Should Use Teardrop Pallet Racking in Your Warehouse

If you are seeking a trustworthy, adaptable, and economical storage solution for your warehouse, teardrop pallet racking may be the right choice for you. Teardrop pallet racking can offer you many benefits for your storage needs, such as:

The Benefits of Teardrop Pallet Racking for Your Storage Needs

Space optimization:

Teardrop pallet racking can help you optimize your storage space, by allowing you to store more pallets and goods in less space. Teardrop pallet racking can be customized and configured to fit your warehouse layout, dimensions, and specifications. You can also adjust the beam height and position, as well as the number and size of the pallets, to maximize the vertical and horizontal space utilization.

Teardrop pallet racking can also be integrated with other storage systems and equipment, such as mezzanine floors, conveyor belts, and automated storage and retrieval systems, to create a multi-level and multi-functional storage system.

Efficiency improvement:

Teardrop pallet racking can help you improve your efficiency, by reducing the time and labor required for storing and retrieving your goods. Teardrop pallet racking provides direct and easy access to each pallet and each SKU, which simplifies the inventory management and order fulfillment processes.

Teardrop pallet racking also enables faster and smoother loading and unloading operations, as it is compatible with most types of forklifts and pallets. Teardrop pallet racking can also increase the productivity and performance of your workers, as it reduces physical strain and fatigue, as well as the risk of errors and accidents.

Safety enhancement:

Teardrop pallet racking can help you enhance your safety, by protecting your workers and your goods from damage and injury. Teardrop pallet racking is durable and robust, as it can withstand heavy loads and impacts, as well as harsh environmental conditions. Teardrop pallet racking also has a locking device that secures the beam in place, preventing it from falling or dislodging.

Teardrop pallet racking can also be equipped with various components and accessories, such as wire decking, column protectors, row spacers, and cross bars, to improve the stability and security of your storage system. Teardrop pallet racking can also help you comply with the safety standards and regulations of your industry and your country, such as the Australian Standard AS4084-2012 for Steel Storage racks.

The Best Practices for Teardrop Pallet Racking Installation, Use and Maintenance

To ensure that you get the most out of your teardrop pallet racking system, you should follow the best practices for its installation, use, and maintenance, such as:

Things to keep in mind when installing teardrop pallet racking:

- To install teardrop pallet racking, you need to plan your layout and design first, considering the size, shape, and weight of your pallets, the available floor space and ceiling height, the aisle width and clearance, and the accessibility and flow of your inventory. You also need to comply with the local building codes and fire safety regulations and consult with a professional engineer if necessary.

- Next, you need to assemble your teardrop pallet racking components, starting with the upright frames. Attach the base plates to the bottom of the uprights, and secure them with anchor bolts to the floor. Make sure the uprights are level and plumb, and use shims if needed to adjust the height. You can also use row spacers to connect the uprights and increase the stability of the frames.

- Then, you need to attach the beams to the uprights. Slide the beam connectors into the teardrop holes on the uprights, and make sure they lock into place with an audible click. You can also use safety clips or pins to prevent the beams from dislodging accidentally. Make sure the beams are level and aligned, and use crossbars or pallet supports to reinforce the load capacity of the beams.

- Finally, you need to add the decking to the beams. You can use wire mesh, wood, or metal decking, depending on your preference and budget. Make sure the decking fits snugly on the beams and does not overhang or sag. You can also use column guards, end-of-aisle protectors, or rack enclosures to protect your teardrop pallet racking system from forklift damage or falling objects.

Daily use of teardrop pallet racking:

- To use teardrop pallet racking, you need to label your pallets and racks clearly and accurately and use a consistent inventory management system. This will help you keep track of your stock, and avoid misplacing or losing items.

- You also need to load and unload your pallets carefully and evenly and avoid overloading or underloading your racks. Follow the manufacturer's specifications and recommendations for the load capacity and weight distribution of your teardrop pallet racking system.

- Moreover, you need to use the right equipment and tools to handle your pallets, such as forklifts, pallet jacks, or hand trucks. Make sure the equipment and tools are in good condition and operated by trained and certified personnel. Follow the safety rules and procedures for operating the equipment and tools, and avoid speeding, reversing, or turning sharply.

- Furthermore, you need to inspect your pallets and racks regularly for any signs of damage, wear, or corrosion. Look for any cracks, bends, dents, or rust on the uprights, beams, or decking. Also check for any loose or missing hardware, such as bolts, clips, or pins. If you find any issues, report them immediately and take the necessary actions to repair or replace the damaged components.

Routine maintenance of teardrop pallet racking:

- To maintain teardrop pallet racking, you need to clean your pallets and racks periodically and remove any dust, dirt, debris, or spills. Use a soft cloth, brush, or vacuum to clean the surfaces, and avoid using harsh chemicals or abrasives that might damage the finish or coating of the components.

- You also need to lubricate the moving parts of your teardrop pallet racking system, such as the beam connectors, clips, or pins. Use a suitable lubricant, such as oil, grease, or wax, and apply it sparingly and evenly. This will help reduce the friction and wear of the parts, and prevent them from sticking or jamming.

- Additionally, you need to adjust the level and alignment of your pallets and racks as needed and make sure they are stable and secure. Use a level, plumb, or tape measure to check the position and angle of the components, and use shims, spacers, or braces to correct any deviations. This will help prevent the pallets and racks from tilting, sagging, or collapsing.

Conclusion

Teardrop pallet racking is a type of selective pallet racking system that uses a teardrop-shaped hole on the upright frames to connect the beams. Teardrop pallet racking is one of the most prevalent and preferred pallet racking systems in the market, due to its compatibility, flexibility, durability, and cost.

Teardrop pallet racking can offer you many benefits for your storage needs, such as space optimization, efficiency improvement, and safety enhancement. Teardrop pallet racking is also easy and quick to install, adjust, and maintain, without the need for tools or hardware. However, teardrop pallet racking also has some drawbacks, such as low storage density and stability issues, that you should be aware of and address accordingly.

If you are interested in teardrop pallet racking for your warehouse, you should contact HEDA, a leading manufacturer and supplier of teardrop pallet racking and other storage solutions. HEDA has over 20 years of experience and expertise in the industry and can provide you with high-quality products, competitive prices, and excellent service.

Recently Reviews

Read MoreLeave a Reply

- Advantages of Gondola Shelving - Why It Is Popular In Retailing

- 9 Ideas To Attract Customers By In-store Merchandising Displays

- Advantages & Features of Pallet Rack Mezzanine for Warehouse

- Fruit And Veg Display Stand - The Best Types & Layout Suggestions

- How To Boost Sales for Shops With Product Display