Heda as one of the leading companies in growth

Heda Shelves as a Chinese leader in storage solutions. The truth is that with an export rate of over 90%, Heda team currently racking has a commercial presence in more than 100 countries. Likewise, it has a technological center where it develops its activity in R&D, a fully automated production center of over 35,000 m2

This year, we expanded two more warehouses to accommodate larger orders, greatly increased monthly output, and ensured stable delivery time for customers, as well as a large number of orders. One of the production lines is equipped with fully automatic machinery, and the daily output can reach 1,300 sets per day. Each factory can reach 5 million orders per month. Heda factory strictly follows the production steps to produce shelves, and all materials are 100% new raw materials, not second-hand materials. The most important pickling and phosphating step can better remove oil and rust on the surface of the material; make the subsequent spray paint better adhere to the surface of the product, ensuring that the product has a service life of at least 15 years. Greatly reduce the customer's procurement cost, so that customers have a better experience.

In the case of industrial racking, knowledge of the raw material, in this case steel, is key because it provides the basis for using the appropriate quality of raw material for each product. Q235 Cold-rolled sheet is our main material which with good performance.

In this phase, a machine that produces rolled steel with advanced, robust and versatile technology will help, through strict control of the profile dimensions, to ensure that the product is always within the established quality parameters.

In a high quality and demanding profiling process, a full list of dimensions must be defined for each manufactured article (beams and uprights in this case), which is continuously checked during each production order. Each critical measurement must be controlled to ensure the correct behaviour of the product, both in the assembly of the installation and under the application of the load.

Welding process

The automated manufacturing system provides uniform welding with an excellent surface finish. Subsequently, any possible defect in this operation is discounted if final control is carried out of all the welded components.

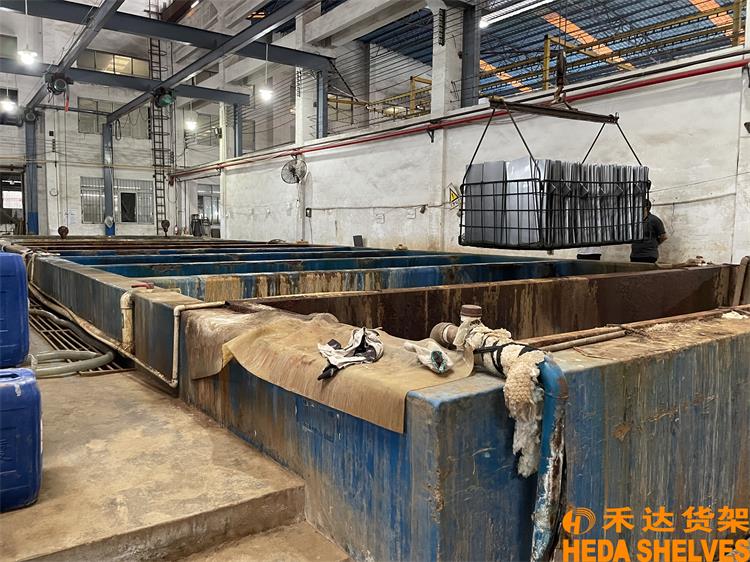

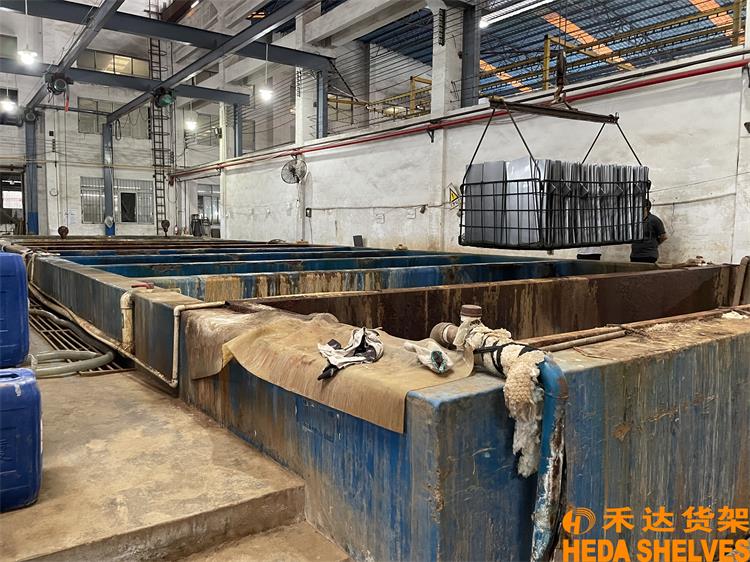

Acid-washing and phosphating is a very important step in storage rack pretreatment, which has a great influence on rack quality and service life.

Acid-washing and phosphating is a very complicated and laborious process. The preliminary treatment of some large factories is Acid-washing and phosphating for a whole day. At present, because of the cost and environmental protection, many factories no longer carry out Acid-washing and phosphating. But Heda will follow strictly on each step, especially on Acid-washing and phosphating.

The difference between Acid-washing and phosphating is that the storage racks without pre-treatment may be the same as the ones that have been treated before leaving the factory, but there is no grease removal, rust removal, phosphating, etc. These things still exist on the surface of the steel workpiece, and the surface looks very good (in fact, the surface can be distinguished, the surface without pretreatment is uneven, with many small bubbles, small spots, etc.), it can be used for a period of time, and if the environment is relatively humid, the paint surface that can be sprayed for half a year will begin to crack and rust and the warehouse rack will be completely rusted after more than a year. Even if the environment is relatively dry, the service life of the storage rack is less than half that of the rack that has been pretreated.

Our aim is “Quality is our Culture”, we are not only selling products to our customers but also quality.

If there is any request pls feel free to contact us, we will offer you good tips to purchase warehouse racks.